America Makes, also known as the National Additive Manufacturing Innovation Institute, will provide up to $8 million in funding toward additive manufacturing (3-D printing) applied research and development projects with $11 million in matching cost share from the awarded project teams for total funding worth $19 million.

If you want to get an idea of the challenges that bigger companies face with additive manufacturing, just take a look at some of these very technical project award descriptions. I am not diminishing what these projects are out to solve, but to simply say that they are complex and detailed projects. The Institute is doing its part to advance additive manufacturing in the United States.

This is the Institute’s third project call, which was released in February 2015, focusing on five technical additive manufacturing topic areas—design, material, process, value chain, and genome—each with additional subset focus areas. Projects are or will be underway this summer. Here are two of the nine funded projects including their technical titles, (acronym-buzz warning):

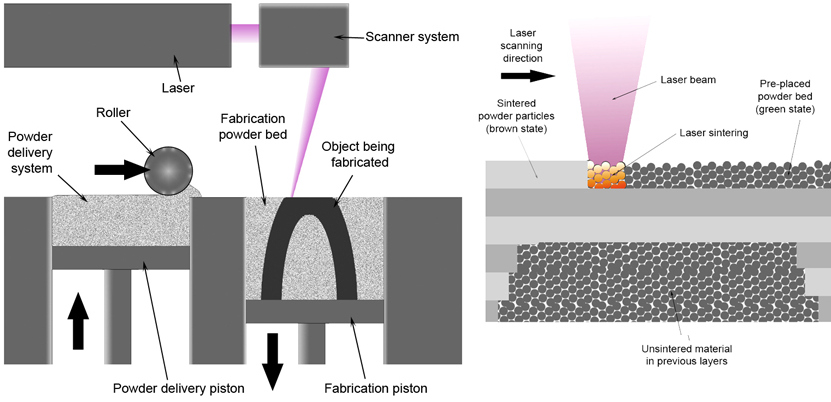

Parametric Design of Functional Support Structures for Metal Alloy Feedstocks: Led by the University of Pittsburgh, in conjunction with Johnson & Johnson JNJ -2.22%, ITAMCO, and the University of Notre Dame, this project will strive to develop parametric designs of functional support structures for metal alloy feedstocks. Specifically, the project team aims to codify the design rules for support structures used in Direct Metal Laser Sintering (DMLS). EOS is known as the inventor of the DMLS method that uses a laser to sinter (almost melting) metal powder, layer by layer, to form the 3-D model into a solid structure.

In most 3-D printing processes, depending on the complexity of the model being printed, the object will need support structures (think of an overlapping part), to hold up the part so that it can keep its shape. ITAMCO told me they are creating some of the software to help with this support optimization because few rules exist for designing support structures. Adding these supports is still fairly primitive and does not consider part orientation, distortion, or heat extraction uniformity.

No comments:

Post a Comment